Applied Statics and Strength of Materials (6th Edition)

6th Edition

ISBN: 9780133840544

Author: George F. Limbrunner, Craig D'Allaird, Leonard Spiegel

Publisher: PEARSON

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

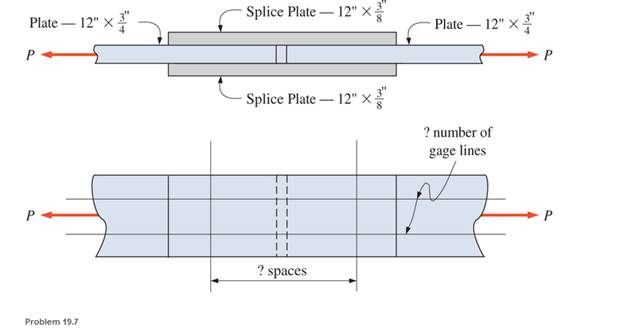

Chapter 19, Problem 19.7P

Select the number and arrangement of

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

3. An M16 x 2 bolt with a slotted hex nut is used to clamp together two 25 mm steel plates. The joint

is assembled with a size 16 N washer underneath the bolt head. The bolt is a 5.8 class metric grade,

with a proof strength of 380 MPa. The joint is intended to be permanent. Determine a suitable length

for the bolt, rounded up to the nearest standard size in millimeters. Calculate the bolt stiffness, the

elongation of the bolt after the necessary preload is developed, and the bolt torque required to apply

the preload. Assume that coefficients of friction between the bolt, nut, and collar are all ~0.15. For

steel, use E = 207 GPa.

Standard threaded fastener lengths, dimensions of hexagonal nuts, and dimensions of metric plain

washers are provided in the textbook appendices.

Two 1/4 in × 8 in A36 steel plates are joined with a lap joint using 3/4 in A325-N bolts. If a concentric unfactored live load of 50 kips (dead load = 0) is required to be resisted by the connection and the bolt shear strength controls the design, the minimum required number of bolts is?

4. Determine the design stress for bolts in a cylinder cover where the load is fluctuating due to gas

pressure. The maximum load on the bolt is 50 kN and the minimum is 30 kN. The load is unpredict-

able and factor of safety is 3. The surface of the bolt is hot rolled and the suface finish factor is 0.9.

During a simple tension test and rotating beam test on ductile materials (40 C 8 steel annealed), the

following results were obtained :

Diameter of specimen =12.5 mm; Yield strength= 240 MPa; Ultimate strength= 450 MPa; Endurance

limit = 180 MPa.

[Ans. 65.4 MPa]

Chapter 19 Solutions

Applied Statics and Strength of Materials (6th Edition)

Ch. 19 - Prob. 19.1PCh. 19 - Rework Problem 19.1 assuming a bearing-type...Ch. 19 - Rework Problem 19.1 assuming a bearing-type...Ch. 19 - Compute the allowable tensile load for the...Ch. 19 - Rework Problem 19.4 assuming a bearing-type...Ch. 19 - Rework Problem 19.4 assuming that the bolts are 34...Ch. 19 - Select the number and arrangement of 34 in....Ch. 19 - Calculate the allowable tensile load for the...Ch. 19 - In the connection shown, 14 in. side and end...Ch. 19 - Design the fillet welds parallel to the applied...

Ch. 19 - A fillet weld between two steel plates...Ch. 19 - Design an end connection using longitudinal welds...Ch. 19 - Calculate the allowable tensile load for the butt...Ch. 19 - Calculate the allowable tensile load for the lap...Ch. 19 - Calculate the allowable tensile load for the butt...Ch. 19 - Rework Problem 19.10 assuming that both plates are...Ch. 19 - Rework Problem 19.12 assuming that the angle is an...Ch. 19 - Two ASTM A36 steel plates, each 12 in. by 12 in. ,...Ch. 19 - Rework Problem 19.20 changing the fasteners to 34...Ch. 19 - Calculate the minimum main plate thickness for the...Ch. 19 - A roof truss tension member is made up of 2L6412...Ch. 19 - Rework Problem 19.23 changing the fasteners to six...Ch. 19 - Determine the allowable tensile load that can be...Ch. 19 - The welded connection shown is subjected to an...Ch. 19 - In Problem 19.26, use a 38 in. fillet weld, change...

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- A 3-in Aluminum plate and a 2-in cast-iron plate are compressed with one bolt and nut. The bolt is 7/8 in-9 UNC. (1) Determine a suitable length for the bolt, rounded up to the nearest in. (2) Determine the bolt stiffness. (3) Determine the stiffness of the members.arrow_forwardUse LRFD and design a 13-foot-long tension member and its connection for a service dead load of 8 kips and a service live load of 24 kips. No slip of the connection is permitted. The connection will be to a 3⁄8-inch-thick gusset plate, as shown in Figure . Use a single angle for the tension member. Use Group A bolts and A572 Grade 50 steel for both the tension member and the gusset plate.arrow_forwardA 5⁄8-inch-thick tension member is connected to two 1⁄4-inch splice plates, as shown in Figure The loads shown are service loads. A36 steel and 5⁄8-inchdiameter, Group A bolts will be used. If slip is permissible, how many bolts are required? Each bolt centerline shown represents a row of bolts in the direction of the width of the plates.arrow_forward

- As shown in figure below, two plates are clamped by washer-faced 2 in-20 UNF SAE grade 5 bolts each with a standard 2 N steel plain washer. The top plate is steel and the bottom pplate is gray cast iron. If a total of 8 bolts where used to close 1 feet diameter pipe which applied at maximum pressure of 150 psi. Calculate the static and fatigue safety factor of this joint. Used Goodman theory for tha fatigue safety 1/2 factor. 3/4arrow_forwardCondition #1: A structural support for a machine is subjected to a static compression load of 20 kN. The support is manufactured from a circular rod made from SAE 1040 Hot Rolled steel. Specify suitable diameter for the cross section of the rod based on the basic size. Steel data are available in Table A-10 from the textbook. Condition #2: The same structural support of the basic size determined in Condition 1 is subjected to a tensile load of 15 kN that is repeated several thousand times over the life of the machine. This load is not an addition to the 20 kN. Specify a suitable steel that is suitable to this application based on the basic size determined in Condition #1. Loading of Condition #1 does not apply here. Condition #3: The same structural support from Condition 2 is heated from room temperature of 25°C. The support is placed inside a frame on both ends. There is a total clearance of 0.2 mm between the support and its frame. Initial length of the rod is 200 mm. Specify the…arrow_forwardAgui - 4550/2 =2276 two plates each with thickness t - 16 mm are bolted together with 6-222 mndia. bolts firming alap Joint Bolt spacing are follows St- $40mm S2 - 80mm, S3=150mm effective bolt hole dia. is 25mm A36 is used. Compute the allowable tensile Strength P t = 16 mm &t 52 747₁ 0 O O 40 60 80 40 +=16mm S-400 $3-100 S2-40 7 @ 4umm Parrow_forward

- An M 14 x 2 hex-head bolt with a nut and a 14R washer under each of bolt head and the nut is used to clamp together two 18-mm steel plates. NOTE: This is a multi-part question. Once an answer is submitted, you will be unable to return to this part. Determine the bolt stiffness. The bolt stiffness kb is 592.69 MN/m.arrow_forwardDesign knuckle joint joint to resist the load of 100 and 150 kN respectively. The material for both joint is 40C8 FS =3arrow_forwardSelect the lightest WT4 shape to be used as a 20 ft long tension member to resist the following service loads: dead load, D = 20 k, live load, L = 35 k, snow load, S = 25 k, and earthquake, E = 50 k. The connection is two lines of bolts through the flange with three 3/4-in Ø bolts in each line spaced at 3 in on center. Use A992 Grade 50 steel. Neglect block shear.arrow_forward

- Select a standard threaded round rod to support a factored tensile load of 35 kips (service tensile load = 25 kips) using A36 steel. (answer 1 1/4-in rod LRFD and ASD)arrow_forwardAn aluminum rod, made from alloy 6061-T6, is made in the form of a hollow square tube, 2.25 in outside with a wall thickness of 0.125 in. Its length is 16.0 in. It carries an axial compressive force of 12 600 lb. Compute the resulting design factor. Assume that the tube does not buckle.arrow_forwardSketch a V-grooved butt joint, and label all of the joint's dimensions.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Welding: Principles and Applications (MindTap Cou...Mechanical EngineeringISBN:9781305494695Author:Larry JeffusPublisher:Cengage Learning

Welding: Principles and Applications (MindTap Cou...Mechanical EngineeringISBN:9781305494695Author:Larry JeffusPublisher:Cengage Learning

Welding: Principles and Applications (MindTap Cou...

Mechanical Engineering

ISBN:9781305494695

Author:Larry Jeffus

Publisher:Cengage Learning

EVERYTHING on Axial Loading Normal Stress in 10 MINUTES - Mechanics of Materials; Author: Less Boring Lectures;https://www.youtube.com/watch?v=jQ-fNqZWrNg;License: Standard YouTube License, CC-BY