Applied Statics and Strength of Materials (6th Edition)

6th Edition

ISBN: 9780133840544

Author: George F. Limbrunner, Craig D'Allaird, Leonard Spiegel

Publisher: PEARSON

expand_more

expand_more

format_list_bulleted

Textbook Question

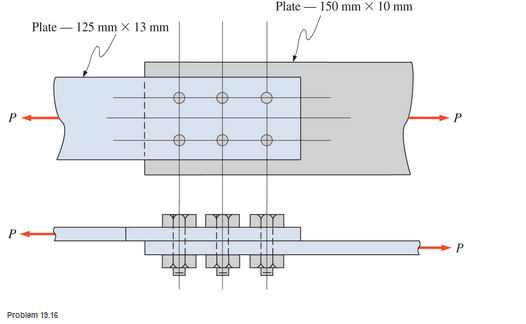

Chapter 19, Problem 19.16SP

Calculate the allowable tensile load for the lap joint shown. The fasteners are 25-mm-diameter A325-X high-strength bolts. The plates are ASTM A36 steel.

Expert Solution & Answer

Trending nowThis is a popular solution!

Students have asked these similar questions

Which of the following is the permissible working stress in psi of UNC bolts that has a stress area of 0.4 sq. in if material used is carbon steel with C = 5000?

Te - Effective throat thickness well in mm = 6 sin45°

Consider the following drawing in which plate 1 is welded onto plate 2 as shown for tensile and shear loading. The plates are fillet welded with a weld thickness of 6 mm as shown for a length of 150 mm.

The plates have an ultimate strength of 275 MPa and the welding was done with F70 welding electrodes, which possesses an ultimate strength of 483 MPa.

Consider a partial factor of safety of 1.7 for the welded joint and determine the design strength of the weld joint, both in tension (Tdw) and in shear (Vdw) due to the forces acting on it.

a) Determine the design strength of the following weld in tension ( ) due to vertical forces.

b) Determine the design strength of the weld in shear ( ) due to horizontal forces.

Attached pic is shear equation for calculation

Tension equation for calculation is: Tdw = FyLwte /Ymw

3. An M16 x 2 bolt with a slotted hex nut is used to clamp together two 25 mm steel plates. The joint

is assembled with a size 16 N washer underneath the bolt head. The bolt is a 5.8 class metric grade,

with a proof strength of 380 MPa. The joint is intended to be permanent. Determine a suitable length

for the bolt, rounded up to the nearest standard size in millimeters. Calculate the bolt stiffness, the

elongation of the bolt after the necessary preload is developed, and the bolt torque required to apply

the preload. Assume that coefficients of friction between the bolt, nut, and collar are all ~0.15. For

steel, use E = 207 GPa.

Standard threaded fastener lengths, dimensions of hexagonal nuts, and dimensions of metric plain

washers are provided in the textbook appendices.

Chapter 19 Solutions

Applied Statics and Strength of Materials (6th Edition)

Ch. 19 - Prob. 19.1PCh. 19 - Rework Problem 19.1 assuming a bearing-type...Ch. 19 - Rework Problem 19.1 assuming a bearing-type...Ch. 19 - Compute the allowable tensile load for the...Ch. 19 - Rework Problem 19.4 assuming a bearing-type...Ch. 19 - Rework Problem 19.4 assuming that the bolts are 34...Ch. 19 - Select the number and arrangement of 34 in....Ch. 19 - Calculate the allowable tensile load for the...Ch. 19 - In the connection shown, 14 in. side and end...Ch. 19 - Design the fillet welds parallel to the applied...

Ch. 19 - A fillet weld between two steel plates...Ch. 19 - Design an end connection using longitudinal welds...Ch. 19 - Calculate the allowable tensile load for the butt...Ch. 19 - Calculate the allowable tensile load for the lap...Ch. 19 - Calculate the allowable tensile load for the butt...Ch. 19 - Rework Problem 19.10 assuming that both plates are...Ch. 19 - Rework Problem 19.12 assuming that the angle is an...Ch. 19 - Two ASTM A36 steel plates, each 12 in. by 12 in. ,...Ch. 19 - Rework Problem 19.20 changing the fasteners to 34...Ch. 19 - Calculate the minimum main plate thickness for the...Ch. 19 - A roof truss tension member is made up of 2L6412...Ch. 19 - Rework Problem 19.23 changing the fasteners to six...Ch. 19 - Determine the allowable tensile load that can be...Ch. 19 - The welded connection shown is subjected to an...Ch. 19 - In Problem 19.26, use a 38 in. fillet weld, change...

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Sketch a V-grooved butt joint, and label all of the joint's dimensions.arrow_forward5. A triple riveted lap joint with zig-zag riveting is to be designed to connect two plates of 6 mm thickness. Determine the dia. of rivet, pitch of rivets and distance between the rows of rivet. Indicate how the joint will fail. Assume : o, = 120 MPa ; t = 100 MPa and o, = 150 MPa. %3D [Ans. d = 14 mm ; p = 78 mm; pb = 35.2 mm] %3Darrow_forwardDesign a cotter joint to support a axial load of122kN kN . Carbon steel material selected which has Tensile stress = 100MPa Compressive stress =150MPa; Shear stress=60MPaarrow_forward

- Determine the safe tensile load for bolts of (a)M 17and (b) M 26. Assume that the bolts are not initially stressed and take the safe tensile stress as 305MPa.arrow_forward4. With tai yield strength of 393MP. JE the factor of safety is 4, calculate the allowable force E Strength of 210MPA. If the factor of safety is 4, calculate the key length. Note: fore circular shape welding A = 1.414 zhr J, = 2 nr F -045 930arrow_forwardTwo plates, 25 mm thick, are welded together by means of trans verse-fillet welds. The ultimate tensile strength of a weld metal is 415 MPa. The surface finish factor of the weld surface is 0.5, and the size factor is 0.85. The reliability is 90%. Determine the length of the weld if the factor of safety is 2. The transverse force on the welds is 100 kN, which is completely reversed under fatigue loading. Take: A=10mm 25 Toe Р.arrow_forward

- A 30-mm thick AISI 1020 steel plate is sandwiched between two 20-mm thick2024-T3 aluminum plates and compressed with a bolt and nut with no washers. The boltis M12 × 1.75, property class 9.8. Draw a sketch of the joint and,(a) Determine a suitable length for the bolt, rounded up to the nearest 5 mm. (b) Determine the bolt stiffness.(c) Determine the stiffness of the members and joint stiffness.arrow_forwardTwo 1/4 in × 8 in A36 steel plates are joined with a lap joint using 3/4 in A325-N bolts. If a concentric unfactored live load of 50 kips (dead load = 0) is required to be resisted by the connection and the bolt shear strength controls the design, the minimum required number of bolts is?arrow_forward3.) The diagram below shows a 5.5m long double angle brace which is connected by 6mm welding connection. The length of weld shown in the picture is 300 mm on the top and 100 mm on the bottom. The 2-L127x 89x6.4 are 300W steel and long leg back-to-back. The braces are to be welded to a 12 mm 350W steel gusset plate. Determine the factored tensile capacity of the angles. Any intermediate connections that are required should also be specified. 740 kN -12 mm Gusset Platearrow_forward

- Discuss the significance of the initial tightening load and the applied load so far as bolts are concerned. Explain which of the loads must be greater for a properly designed bolted joint and explain how each affects the total load on the bolt.arrow_forwardDetermine the safe tensile load for bolts of (a) M 17 and (b) M 26. Assume that the bolts are not initially stressed and take the safe tensile stress as 305 MPaarrow_forwardPre-tensioning of a bolted joint is used to (a) strain harden the bolt head (b) decrease stiffness of the bolted joint (c) increase stiffness of the bolted joint (d) prevent yielding of the thread rootarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Welding: Principles and Applications (MindTap Cou...Mechanical EngineeringISBN:9781305494695Author:Larry JeffusPublisher:Cengage Learning

Welding: Principles and Applications (MindTap Cou...Mechanical EngineeringISBN:9781305494695Author:Larry JeffusPublisher:Cengage Learning

Welding: Principles and Applications (MindTap Cou...

Mechanical Engineering

ISBN:9781305494695

Author:Larry Jeffus

Publisher:Cengage Learning

Differences between Temporary Joining and Permanent Joining.; Author: Academic Gain Tutorials;https://www.youtube.com/watch?v=PTr8QZhgXyg;License: Standard Youtube License