(a)

The critical speed of the trommel screen.

Answer to Problem 5.11P

Explanation of Solution

Given:

The diameter of trommel screen is

The length of trommel screen is

The angle of inclination is

Concept Used:

Write theexpression to calculate the critical speed of trommel screen.

Here, the acceleration due to gravity is

Calculation:

Calculate the critical speed of trommel screen.

Substitute

Conclusion:

Thus, the critical speed of trommel screen is

(b)

The type of movement of MSW in the trommel screen.

Answer to Problem 5.11P

The movement of MSW in trommel screen is cataracting.

Explanation of Solution

Given:

The speed of trommelis

The feed rate is

Calculation:

The movement of MSW is determined by using the relation

Here,

Hence the movement of MSW is either cascading or cataracting.

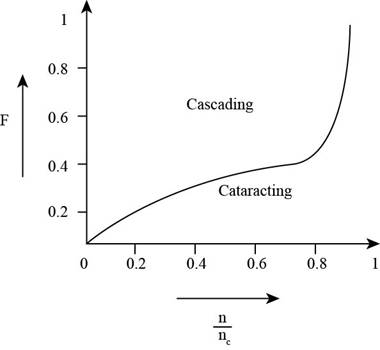

The critical speed and the fraction of the screen occupied by the refuse are related which gives the process of movement of MSW.

Write the equation to calculate the bulk volume.

Here, the bulk volume of trommel screen is

Consider a single particle in the screen.

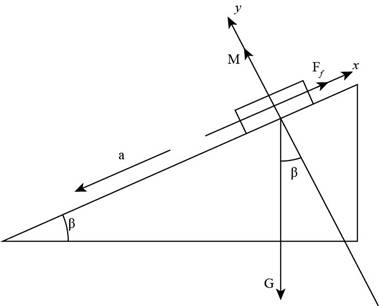

The following figure shows the force analysis diagram.

Figure-(1)

Here, gravity is

Write the equilibrium equation for the x and y axis as shown in Figure-(1).

Here, the coefficient of friction is

Write the equation to calculate acceleration.

Here, the acceleration is

Substitute

Calculate time for particle to move from end to end.

Here, the length is

Substitute

Calculate the volume occupied by the solids and the air spaces between the solids.

Here, the mass flow rate is

Convert the unit of

Convert the unit of time to

Substitute

Calculate the total volume inside the trommel screen.

Substitute

Calculate the bulk volume of trommel screen.

Substitute

The following graph shows critical speed and the fraction of the screen occupied by the refuse are related which gives the process of movement of MSW.

Figure-(2)

Since,

Conclusion:

The type of movement is calculated by equating time, bulk volume, mass flow, density, speed and feed rate.

Want to see more full solutions like this?

Chapter 5 Solutions

Solid Waste Engineering

- Two materials, A and B, are to be separated using two unit operations, 1 and 2. The feed has 10 tons/h A and 4 tons/h B. The split (fraction of material rejected by each operation) is given in Table P5-14. a. Which sequence of operations, (l?2) or (2?1), will yield the greatest recovery of material A? b. What will be the purity of material A using that sequence? c. What will be the efficiency of separation for the entire process train with regard to material A using the Worrell-Stesed equation?arrow_forwardShort out this problemarrow_forwardWhat is an electrostatic precipitator? Explain its working.arrow_forward

- Draw the free-body diagram of each part of the smooth piston andlink mechanism used to crush recycled cans, shown.arrow_forwardFor preparing PCC, would you prefer round and smooth aggregate or rough and angularaggregate? Briefly explain why (no more than two lines).b. For preparing HMA, would you prefer round and smooth aggregate or rough and angularaggregate? Briefly explain why (no more than two lines).arrow_forwardA steel block of size 300 mm X 150 mm X 100 mm subjected to load of 300 kN (tension) on 150 mm X 100 mm face, 500 kN (compression) on 300 mm X 150 mm face and 100 kN (tension) on 300 mm X 100 mm face. Determine change in volume if poisons ratio is 0.25, E = 2 X 10^5 MPaarrow_forward

- Where does the e vibrocompaction process can be used?arrow_forward7. A sample of fine aggregate weighs 544 g when SSD and 530 g when OD. The flask weighs 654 g when filled with water and 985 g when filled with fine aggregate and water. Calculate the bulk specific gravity, apparent specific gravity, and absorption.arrow_forwardliquid limit was 25.72%.arrow_forward

- 6. Two 8 x 4 x 1 inch blocks of foam are glued together (one block on top of the other) and used to support the bottom face of a product. The product weights 15 pounds. The stiffness of each of the blocks respectively is 50 lb/in and 25 lb/in. When the product is placed on the blocks of foam ... a) What is the total foam deflection? b) What is the static load on the foam block? c) What is the natural frequency of the total system?arrow_forwardAggregate from three sources having bulk specific gravities of 2.90, 2.70, and 2.60 was blended at a ratio of 60:30:10 by weight, respectively. What is the bulk specific gravity of the aggregate bled? Select one: O a. 2.87 O b. 2.81 O c. 2.75 O d. 2.65arrow_forwardIl Consider the capability of a process that puts pressurized grease in an aerosol can. The design specification calls for an average of 50 pounds per square inch (psi) of pressure in each can with an upper tolerance limit of 56psi and a lower tolerance limit of 46psi. A sample is taken from production, and it is found that the cans average 51psi with a standard deviation of 2psi. Find the following unknowns. 1. Capability Index (Cpk) 2. Is the process capable at the 30 level? 3. What is the probability of producing a defect? Hind: use the standard normal table as seen below.arrow_forward

Solid Waste EngineeringCivil EngineeringISBN:9781305635203Author:Worrell, William A.Publisher:Cengage Learning,

Solid Waste EngineeringCivil EngineeringISBN:9781305635203Author:Worrell, William A.Publisher:Cengage Learning,