Concept explainers

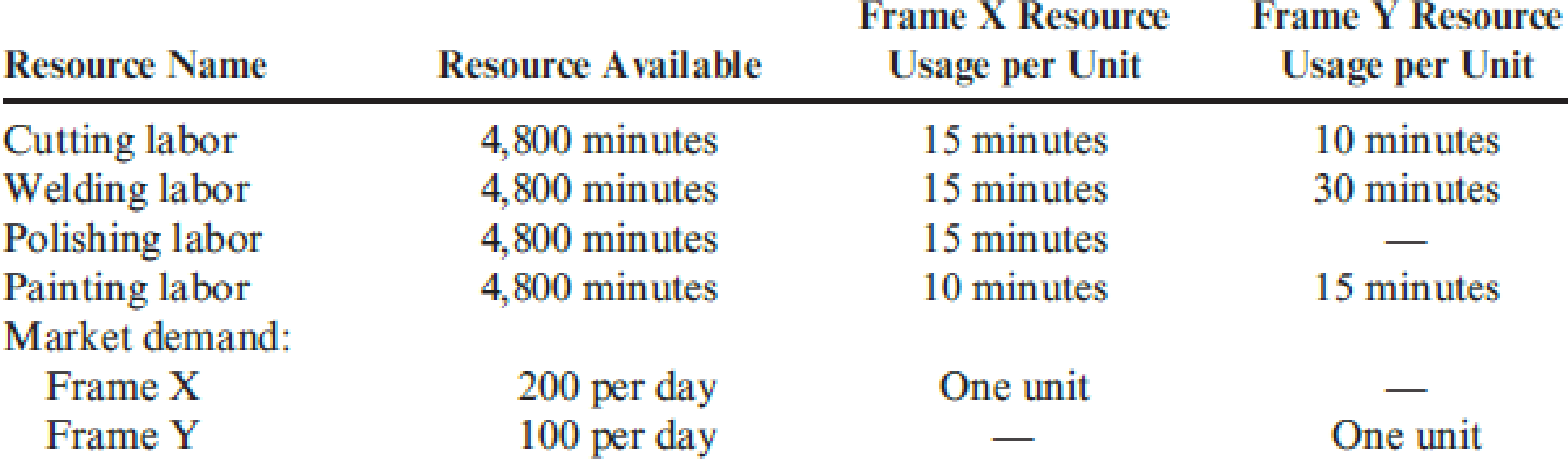

Bountiful Manufacturing produces two types of bike frames (Frame X and Frame Y). Frame X passes through four processes: cutting, welding, polishing, and painting. Frame Y uses three of the same processes: cutting, welding, and painting. Each of the four processes employs 10 workers who work eight hours each day. Frame X sells for $40 per unit, and Frame Y sells for $55 per unit. Materials is the only unit-level variable expense. The materials cost for Frame X is $20 per unit, and the materials cost for Frame Y is $25 per unit. Bountiful’s accounting system has provided the following additional information about its operations and products:

Bountiful’s management has determined that any production interruptions can be corrected within two days.

Required:

- 1. Assuming that Bountiful can meet daily market demand, compute the potential daily profit. Now, compute the minutes needed for each process to meet the daily market demand. Can Bountiful meet daily market demand? If not, where is the bottleneck? Can you derive an optimal mix without using a graphical solution? If so, explain how.

- 2. Identify the objective function and the constraints. Then, graph the constraints facing Bountiful. Determine the optimal mix and the maximum daily contribution margin (throughput).

- 3. Explain how a drum-buffer-rope system would work for Bountiful.

- 4. Suppose that the Engineering Department has proposed a process design change that will increase the polishing time for Frame X from 15 to 23 minutes per unit and decrease the welding time from 15 minutes to 10 minutes per unit (for Frame X). The cost of process redesign would be $10,000. Evaluate this proposed change. What step in the TOC process does this proposal represent?

1.

Ascertain the potential daily profit and calculate the minutes of each process needed to meet the daily market demand. Explain whether Company B could meet the daily market demand and if not state the bottleneck that is placed and derive an optimal mix without using a graphical solution and explain the manner in which it is derived.

Explanation of Solution

Theory of constraint: Making money in the future by managing constraints is the main goal of the theory of constraints. The theory of constraints (TOC) recognizes the performance of origination with constraints volume and it develops a specific approach to focus the system level effects of the continuous improvement.

Ascertain the potential daily profit:

| Particulars | Frame X | Frame Y |

| Sales | $40 | $55 |

| Materials | 20 | 25 |

| Contribution margin per unit (a) | $20 | $30 |

| Market demand (b) | 200 | 100 |

| Daily profit | $4,000 | $3,000 |

| Total potential daily profit | $7,000 | |

Table (1)

Calculate the minutes of each process needed to meet the daily market demand. Explain whether Company B could meet the daily market demand and if not state the bottleneck that is placed and derive an optimal mix without using a graphical solution and explain the manner in which it is derived:

| Process | Resource Demands | Resource Supply |

| Cutting: | ||

| For Frame X | ||

| For Frame Y | ||

| 4,000 | 4,800 | |

| Welding: | ||

| For Frame X | ||

| For Frame Y | ||

| 6,000 | 4,800 | |

| Polishing: | ||

| For Frame X | 4,800 | |

| Painting: | ||

| 3,500 | 4,800 |

Table (2)

Company B cannot meet daily demand. Even though all other processes have excess capacity, the welding process has a low capacity and it requires 6,000 minutes however only 4,800 is available. Thus, welding is the bottleneck. The contribution margin per unit of welding resource (minutes) for each product is computed as follows:

For Frame X:

For Frame Y:

From this calculation it is understood that the company should produce Frame X first. Therefore, out of 4,800 minutes, 3,000 minutes

2.

Identify the objective function and the constraints and then draw a graph for the constraints. Ascertain the optimal mix and the maximum daily contribution margin (throughput).

Explanation of Solution

Contribution margin: Contribution margin is a measurement of performance where only revenue and variable costs are taken into consideration. Hence, this measurement is useful in the evaluation of the probable outcomes of decisions including pricing decisions and other marketing strategies that affect primarily revenue and variable costs.

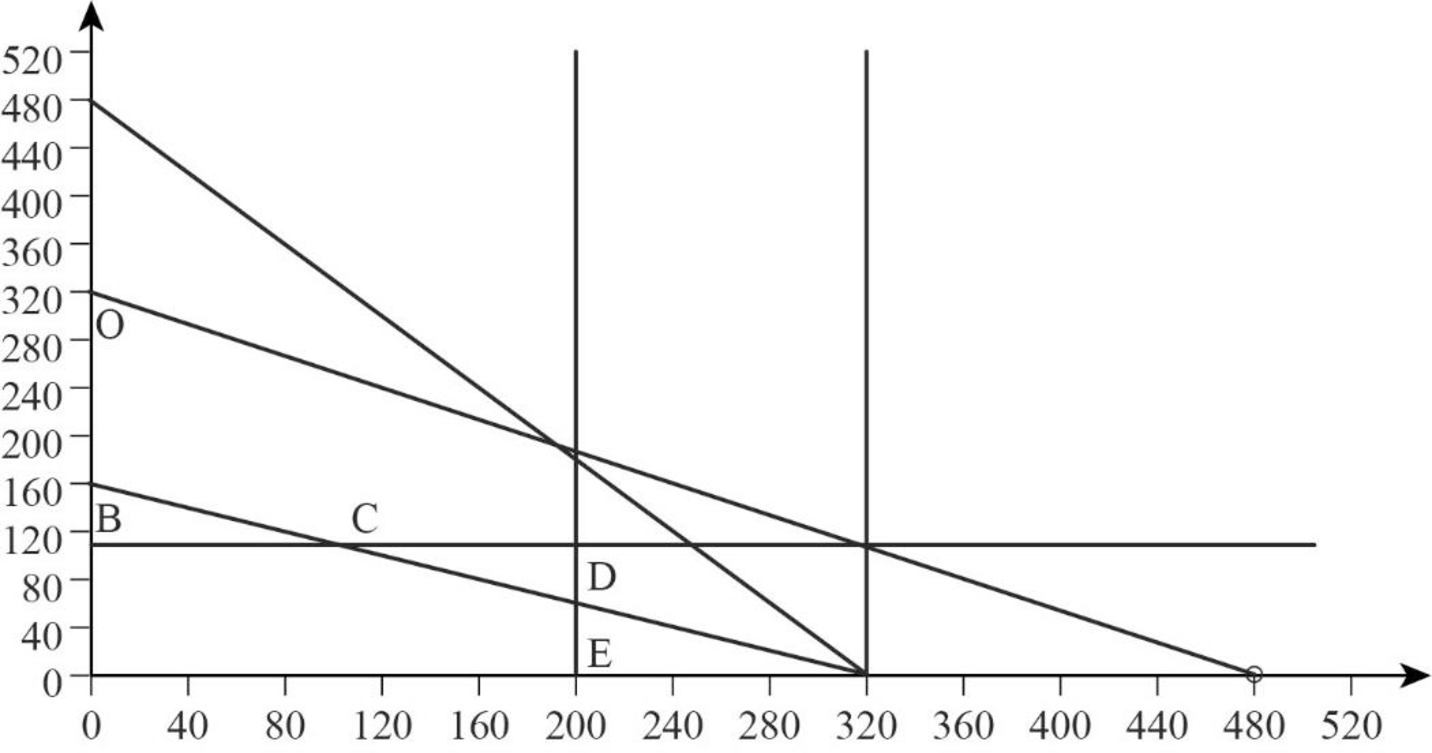

Identify the objective function and the constraints and then draw a graph for the constraints. Ascertain the optimal mix and the maximum daily contribution margin (throughput):

Figure (1)

| Corner point | X | Y | |

| A | 0 | 0 | $0 |

| B | 0 | 100 | $3,000 |

| C | 120 | 100 | $5,400 |

| D | 200 | 60 | $5,800 |

| E | 200 | 0 | $4,000 |

Table (3)

Objective function:

Subject to:

3.

Explain the manner in which a drum-buffer-rope system would work for company B.

Explanation of Solution

The welding process is the drummer in this case and, for the entire plant the drummer sets the production rate. As per the optimal mix, the plant should produce 200 units of Frame X and 60 units of Frame Y each day. In order to ensure that these rates are not exceeded by the cutting process, the release of materials is tied to the maximum production rate of the welding process. Finally, in front of the welding process, a time buffer is set up to protect throughput. Thus, this buffer would contain of 400 cut units of Frame X and 200 cut units of Frame Y for two days.

4.

Evaluate the given proposed change and define the steps in the theory of constrains (TOC) process that is represented by the given proposal.

Explanation of Solution

| Process | Resource Demands | Resource Supply |

| Cutting: | ||

| For Frame X | ||

| For Frame Y | ||

| 4,000 | 4,800 | |

| Welding: | ||

| For Frame X | ||

| For Frame Y | ||

| 5,000 | 4,800 | |

| Polishing: | ||

| For Frame X | 4,800 | |

| Painting: | ||

| 3,500 | 4,800 |

Table (4)

In this case, the redesigning process would reduce the welding time of Frame X from 3,000 minutes to 2,000 minutes and also it increases the polishing time of Frame X from 3,000 minutes to 4,600 minutes. Thus, this decreases the excess capacity of polishing process as well as releases 1,000 minutes of scarce resource in welding process. Thus these 1,000 minutes of scarce resource could be used to produce an additional 33 units of Frame Y

Want to see more full solutions like this?

Chapter 20 Solutions

Cornerstones of Cost Management (Cornerstones Series)

- Box Springs, Inc., makes two sizes of box springs: twin and double. The direct material for the twin is $25 per unit and $40 s used in direct labor, while the direct material for the double is $40 per unit, and the labor cost is $50 per unit. Box Springs estimates it will make 5,000 twins and 9,000 doubles in the next year. It estimates the overhead for each cost pool and cost driver activities as follows: How much does each unit cost to manufacture?arrow_forwardPatz Company produces two types of machine parts: Part A and Part B, with unit contribution margins of 300 and 600, respectively. Assume initially that Patz can sell all that is produced of either component. Part A requires two hours of assembly, and B requires five hours of assembly. The firm has 300 assembly hours per week. Required: 1. Express the objective of maximizing the total contribution margin subject to the assembly-hour constraint. 2. Identify the optimal amount that should be produced of each machine part and the total contribution margin associated with this mix. 3. What if market conditions are such that Patz can sell at most 75 units of Part A and 60 units of Part B? Express the objective function with its associated constraints for this case and identify the optimal mix and its associated total contribution margin.arrow_forwardPower Corp. makes 2 products: blades for table saws and blades for handsaws. Each product passes through the sharpening machine area, which is the chief constraint during production. Handsaw blades take 15 minutes on the sharpening machine and have a contribution margin per blade of $15. Table saw blades take 20 minutes on the sharpening machine and have a contribution margin per blade of $35. If it is assumed that Power Corp. has 5,000 hours available on the sharpening machine to service a minimum demand for each product of 4,000 units, how much will profits increase if 200 more hours of machine time can be obtained?arrow_forward

- Power Corp. makes 2 products: blades for table saws and blades for handsaws. Each product passes through the sharpening machine area, which is the chief constraint during production. Handsaw blades take 15 minutes on the sharpening machine and have a contribution margin per blade of $15. Table saw blades take 20 minutes on the sharpening machine and have a contribution margin per blade of $35. If it is assumed that Power Corp. has 5,000 hours available on the sharpening machine to service a minimum demand for each product of 4,000 units, how many of each product should be made?arrow_forwardBobcat uses a traditional cost system and estimates next years overhead will be $800.000, as driven by the estimated 25,000 direct labor hours. It manufactures three products and estimates the following costs: If the labor rate is $30 per hour, what is the per-unit cost of each product?arrow_forwardColonels uses a traditional cost system and estimates next years overhead will be $480,000, with the estimated cost driver of 240,000 direct labor hours. It manufactures three products and estimates these costs: If the labor rate is $25 per hour, what is the per-unit cost of each product?arrow_forward

- Fogerty Company makes two products—titanium Hubs and Sprockets. Data regarding the two products follow: DirectLabor-Hours per Unit AnnualProduction Hubs 0.70 19,000 units Sprockets 0.30 47,000 units Additional information about the company follows: Hubs require $35 in direct materials per unit, and Sprockets require $12. The direct labor wage rate is $11 per hour. Hubs require special equipment and are more complex to manufacture than Sprockets. The ABC system has the following activity cost pools: Estimated Activity Activity Cost Pool (Activity Measure) Overhead Cost Hubs Sprockets Total Machine setups (number of setups) $ 12,825 75 60 135 Special processing (machine-hours) $ 220,000 4,400 0 4,400 General factory (organization-sustaining) $ 238,900 NA NA NA Required: 1. Compute the activity rate for each activity cost pool. 2. Determine the unit product cost of each product according to the ABC system.arrow_forwardFogerty Company makes two products-titanium Hubs and Sprockets. Data regarding the two products follow: Direct Labor-Hours per Unit Hubs Sprockets Additional information about the company follows: a. Hubs require $36 in direct materials per unit, and Sprockets require $10. b. The direct labor wage rate is $13 per hour. c. Hubs require special equipment and are more complex to manufacture than Sprockets. d. The ABC system has the following activity cost pools: 0.80 0.40 Annual Production 20,000 units 50,000 units Activity Cost Pool (Activity Measure) Machine setups (number of setups) Special processing (machine-hours) General factory (organization-sustaining) Required 1 Required 2 Required: 1. Compute the activity rate for each activity cost pool. 2. Determine the unit product cost of each product according to the ABC system. Complete this question by entering your answers in the tabs below. Compute the activity rate for each activity cost pool. Activity Cost Pool Machine setups Special…arrow_forwardAtlanta Systems produces two different products, Product A, which sells for $650 per unit, and Product B, which sells for $1,200 per unit, using three different activities: Design, which uses Engineering Hours as an activity driver; Machining, which uses machine hours as an activity driver; and Inspection, which uses number of batches as an activity driver. The cost of each activity and usage of the activity drivers are as follows: Usage by Product A Usage by Cost Product B Design (Engineering Hours) Machining (Machine Hours) Inspection (Batches) $ 230,000 $2,600,000 $ 240,000 116 134 2,320 2,680 34 46 Atlanta manufactures 12,500 units of Product A and 10,172 units of Product B per month. Each unit of Product A uses $100 of direct materials and $45 of direct labor, while each unit of Product B uses $140 of direct materials and $75 of direct labor. Required: a. Calculate the activity rate for design. Rate for Design per hour b. Calculate the activity rate for machining. Rate for…arrow_forward

- XYZ Co. produces two different products (Product Y and Product Z) using two different activities: Machining, which uses machine hours as an activity driver, and Inspection, which uses number of batches as an activity driver. The cost of Machining is $500,000, while the cost of Inspection is $30,000. Product Y uses 20% of total machine hours and 75% of total batches. What is the total Machining cost assigned to Product Z? O a. $7,500 O b. None of the given answer is correct. Oc. $22,500 О с. O d. $400,000 O e. $375,000arrow_forwardBecky's Bakery produces two products, cake and pie. Becky's Bakery sells each cake for $15.00 and each pie for $10.00. Variable costs for cakes and pies are respectively, $7.00 and $6.00. There are 3,200 direct labor hours per month available for producing one of the two products. Fixed manufacturing overhead cost is allocated at $1,000 per month. Each cake and pie require 2 direct labor hours. Compute the following: A. Contribution margin per unit for each product. B. Contribution margin per direct labor hour for each product. C. The total number of products produced if only that product is produced each month. D. Income for a month if only one product is produced and total production is sold.arrow_forwardXYZ Co. produces two different products (Product Y and Product Z) using two different activities: Machining, which uses machine hours as an activity driver, and Inspection, which uses number of batches as an activity driver. The cost of Machining is $500,000, while the cost of Inspection is $30,00 Product Y uses 20% of total machine hours and 75% of total batches. What is the total Machining cost assigned to Product Y? O a. None of the given answer is correct. O b. $100,000 O c. $375,000 O d. $7,500 O e. $22,500 NEXT PAGE POR Esc Ftock F1 F2 F4 FB F6 F7 F8 F9 F10 23 24 % & 3. 6. 7 V 8 IS CF 1G H K L. 3 CV B y NiMarrow_forward

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage LearningPrinciples of Accounting Volume 2AccountingISBN:9781947172609Author:OpenStaxPublisher:OpenStax College

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage LearningPrinciples of Accounting Volume 2AccountingISBN:9781947172609Author:OpenStaxPublisher:OpenStax College